How It’s Made: Get a Handle on It!

Get a Handle on It! -by DeWitt Kendall

The handle on a mug can make or break a mug. How we like a mug handle to fit in our hand is a very personal thing and men and women have different likes and dislikes. The mug body can probably vary a lot more than the handle. Going too far out there on a handle shape and it becomes uncomfortable.

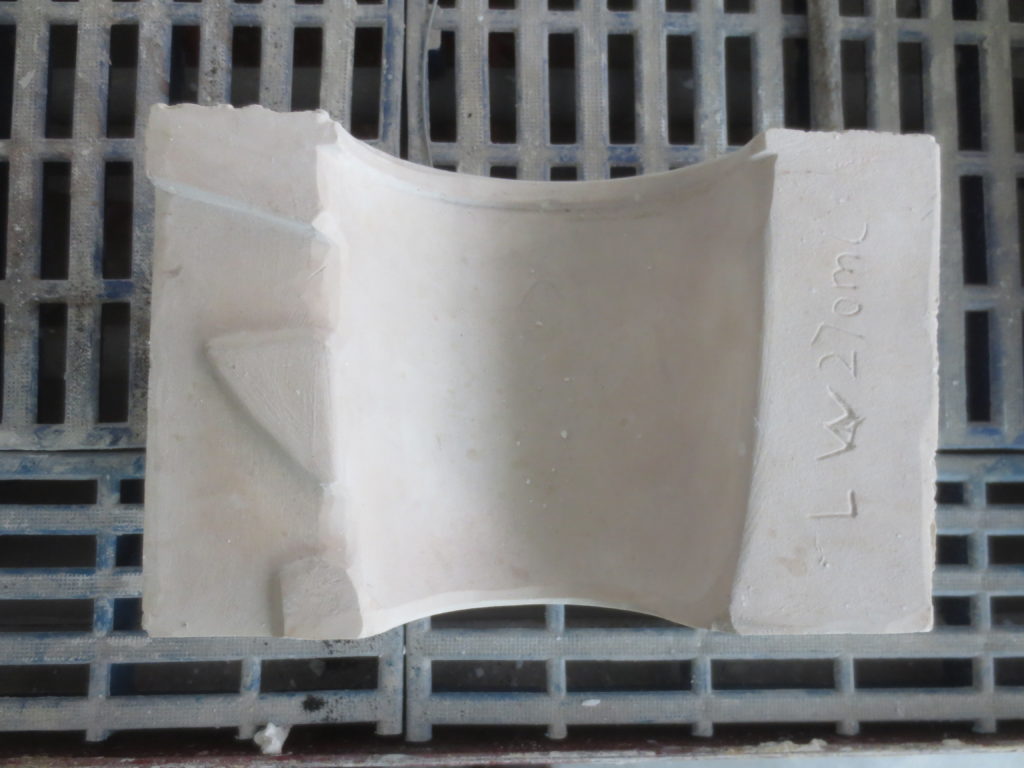

Mug handles are usually what’s called an ‘attachment.’ There are some mugs that have a handle cast onto the body of the mug when the mug body is cast but that’s pretty uncommon and usually found only on very fancy handles that have several attachment points to the body of the mug besides jut the top and the bottom of the handle. Attached handles are almost always cast using a liquid clay mixture. Hand formed handles are usually only used in non-commercial ‘studio pottery’ situations.

There are two primary types of moulds for casting handles.

- Block slip casting. This is where a block of mould openings is filled by pouring or injecting the liquid clay mixture from the top.

- Centrifugal casting. This is where a circular mould is spun at high speed and the liquid clay is poured into the center and is forced out into the extremities of the mould.

Attaching the handles

Nearly every factory has its own method for attaching the handles. The reason for the differences between factories has to do with how tight the tolerance needs to be for the exact placement of the handle. Most workers end up coming within a few millimeter’s tolerance just eyeballing the handle placement which is fine in most cases for most factories. In some cases, however, a few milimeter’s is not acceptable such as cases where the mug will later get a decal that goes right up to the mug handle. Such an application requires that the handle be in pretty much the exact same spot on every mug. In those cases, the factory may cast jigs to lay both the mug body and handle into to put them in the exact same place from mug to mug for handle placement. Some factories use a fixed set-up of laser pointers to guide workers in marking the same place on each mug to tell the person attaching the handle where the handle goes.

Left: Decal placement prior to decal firing. Right: Finished fired decal showing the position of the decal relative to the position of the handle.